Constructing a new building on top of existing structure can sometimes feel like trying to fit a square peg into a round hole. That’s the problem that designers faced in the construction of a 25-story residential tower on top of an existing 8-story concrete garage. In an effort to respond to market changes, the developer abandoned the plans for a square hotel tower with a large light core. Instead a football-shaped condo building that maximized window space was desired.

Constructing a new building on top of existing structure can sometimes feel like trying to fit a square peg into a round hole. That’s the problem that designers faced in the construction of a 25-story residential tower on top of an existing 8-story concrete garage. In an effort to respond to market changes, the developer abandoned the plans for a square hotel tower with a large light core. Instead a football-shaped condo building that maximized window space was desired.The immediate problem faced by the design engineers was how to support the new tower on the existing base. The tower columns did not align with the existing grid, and the structure itself was centered over columns and foundations that were not designed for such loading. In addition, the podium’s lateral system was primarily located outside of the envelope of the planned tower.

Remembering their approach to a similar problem in which a new building planned to reuse existing drilled-pier foundations, the engineers envisioned a 6’-0” deep transfer mat on top of the parking garage. In addition a 16’-0” deep transfer girder was introduced along the center of the mat to further alleviate load from the smaller interior columns. Computer analysis helped determine the required size and reinforcing of the structural members. About 500 tons of steel reinforcing were required for the transfer mat.

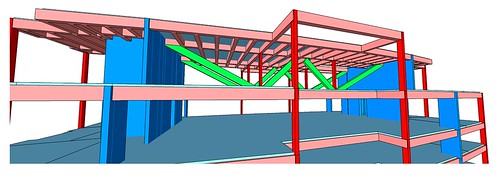

Remembering their approach to a similar problem in which a new building planned to reuse existing drilled-pier foundations, the engineers envisioned a 6’-0” deep transfer mat on top of the parking garage. In addition a 16’-0” deep transfer girder was introduced along the center of the mat to further alleviate load from the smaller interior columns. Computer analysis helped determine the required size and reinforcing of the structural members. About 500 tons of steel reinforcing were required for the transfer mat.However, in order to make the transfer mat and girder system economical, the residential tower needed to be as light as possible. A steel framing system was found to be the best option. A wind tunnel test revealed that the local wind environment funneled winds off of Lake Michigan and could excite the tower in a twisting motion. Although the building was sufficiently strong to resist these winds, the particular motion had the potential to upset the occupants.

The design engineers immediately began discussing options with the architect and developers. Stiffness of the tower played the biggest role in reducing the uncomfortable wind-induced accelerations. The engineers proposed changing the lateral system to a stiff cast-in-place concrete shear wall system. Large openings in the wall were required to accommodate the condominium units’ floor plans. And for even greater stiffness in the east-west direction, a hat truss was added at the 31st floor to link the cores located at either end of the tower.

The construction team likewise faced challenges with the site. The first major construction challenge was figuring out how to support six feet of wet concrete from a series of lightweight post-tensioned parking decks. The supermarket on the 1st floor would have to remain open throughout construction, so it was not possible to shore down to grade. Moreover, the existing parking floors could not support all six feet of wet concrete. Instead, the transfer mat was constructed in two lifts. The first 3’-6” lift included additional shear transfer reinforcement and was designed to support the full wet weight of the remaining mat layer. In this way, the parking decks were actually re-opened ahead of schedule.

With some engineering, the square peg can be fit into the round hole. In this case, a 25-story residential tower was engineered to fit on an existing podium. Creative solutions for distributing gravity load and resisting lateral forces enabled the developers to create a building that could succeed in the current economic environment – even if that meant a drastic departure from the originally designed program.

In what other ways might the design team have addressed these challenges? Could the need to pump so much wet concrete 8-stories above ground have been avoided? Comment below or contribute to the willitstand wiki.

Acknowledgements:

Destefano & Partners, 330 North Wabash, Suite 3200, Chicago, Illinois

Linn –Mathes Inc., 309 South Green Street, Chicago, Illinois

Thornton Tomasetti, 330 North Wabash, Suite 1500, Chicago, Illinois

![Reblog this post [with Zemanta]](http://img.zemanta.com/reblog_e.png?x-id=7e379661-6d2e-4695-baa5-5f78e56dbad7)

0 comments on "Will it stand on a parking garage?"

Post a Comment